We are a Trenchless Industry Innovator, making CSS the Contractor of choice for Communities throughout Canada.

Turn-key system inspection, assessment, maintenance and rehabilitation services.

We are a Trenchless Industry Innovator, making CSS the Contractor of choice for Communities throughout Canada.

Turn-key system inspection, assessment, maintenance and rehabilitation services.

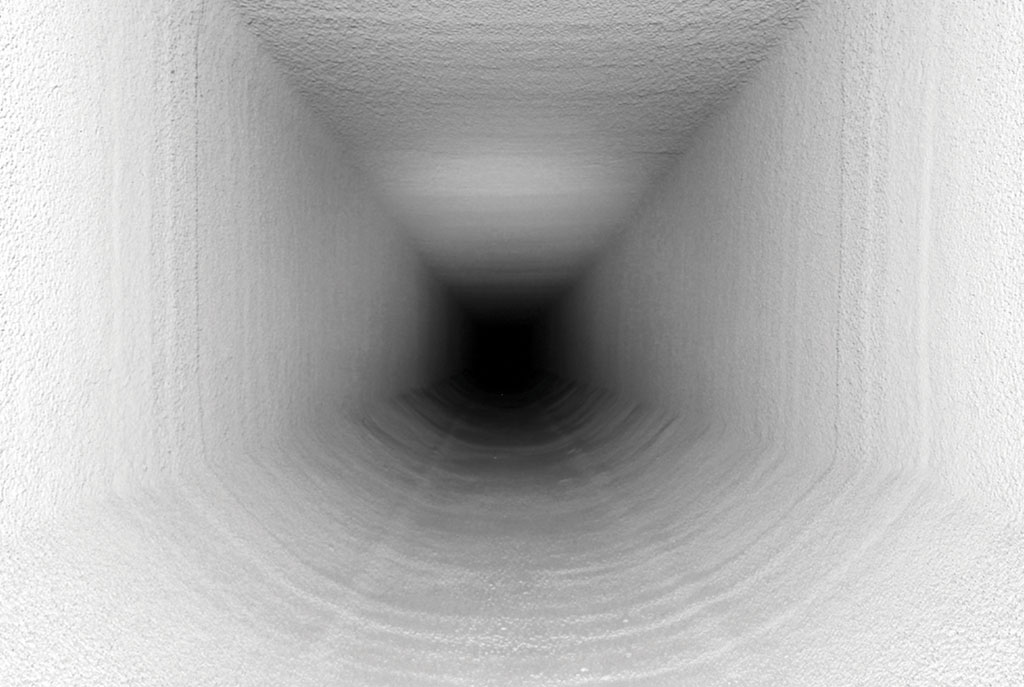

A cured-in-place-pipe (CIPP) is one of several trenchless rehabilitation methods used to repair existing pipelines. Here at Capital Sewer Services, we have the capability of, depending on the requirement, repairing various sized pipes. We offer Volatile Organic Compound (VOC) Free systems when working in storm systems, culverts and outfalls. These systems use felt or fiberglass impregnated with resin and then cured inside the existing pipe. The end result is a strong, ASTM approved product. Applications for CIPP include: large diameter point to point repair, sewer laterals, and building lining.

Our highly trained team, state of the art equipment and advanced repair materials will efficiently restore damaged manholes back to a “like new” condition, giving them another 50 years or more of service. Depending on your manhole conditions, we will specify the right product to meet the need, from corrosion protection to full structural renewal.

The concept of glass-reinforced plastic is a remarkably stiff and strong panel section with a relatively thin wall. The product differs from standard GRP hand or filament wound pipework in many different ways. Normal GRP pipework consists of windings of layers of resin-saturated glass, with sand, achieving its stiffness by thick walls. Glass-reinforced plastic gets its strength and stiffness through a different method, employing the mechanics of a sandwich-like design, incorporating a unique polymer and aggregate core.

Thanks to the geopolymer lining system, we can restore a wide variety of pipes and tunnels. A Geopolymer is not an epoxy or a plastic blended with aggregate; instead, it is a formulated mortar composed of aluminosilicate powder with an alkaline activator to form a solid mineral polymer with ceramic properties.

Due to its chemical composition, Geopolymer is inherently resistant to the prevalence of microbial-induced corrosion in many sewer environments. It contains significantly reduced concentrations of calcium hydrates, commonly found in cementitious mortars, furthering its suitability in low PH environments.

Chemical grouting of sewer mains to control groundwater infiltration has become the mainstay of many sewer system maintenance and rehabilitation programs.

However, excessive infiltration can be costly due to the issues of excavation, disruption of traffic, or by-pass pumping of sewage. Pipe condition, type of leak and soil, chemicals present in the sewage and groundwater pressure should be considered before selecting a chemical or catalyst combination. This is why we focus our attention on sealing lateral connections using chemical grout. The grout is chemically formulated specifically for sewer applications, including acrylamide grout complying with ASTM F2304.

When finishing the job, we seal leaks in service laterals in unlined pipes and seal the annular gap in lined pipes at the lateral connections.

Here at Capital Sewer Services we understand every sewer bypass, pumping and dewatering need is unique. Our experienced team is happy to assess, build and operate the bypass system that best suits your needs. We provide 24/7 pump watch to ensure maximum operating efficiency and also minimize surface disruption and traffic control throughout the operation. When the project is completed, rest assured we restore the affected areas to their original condition.

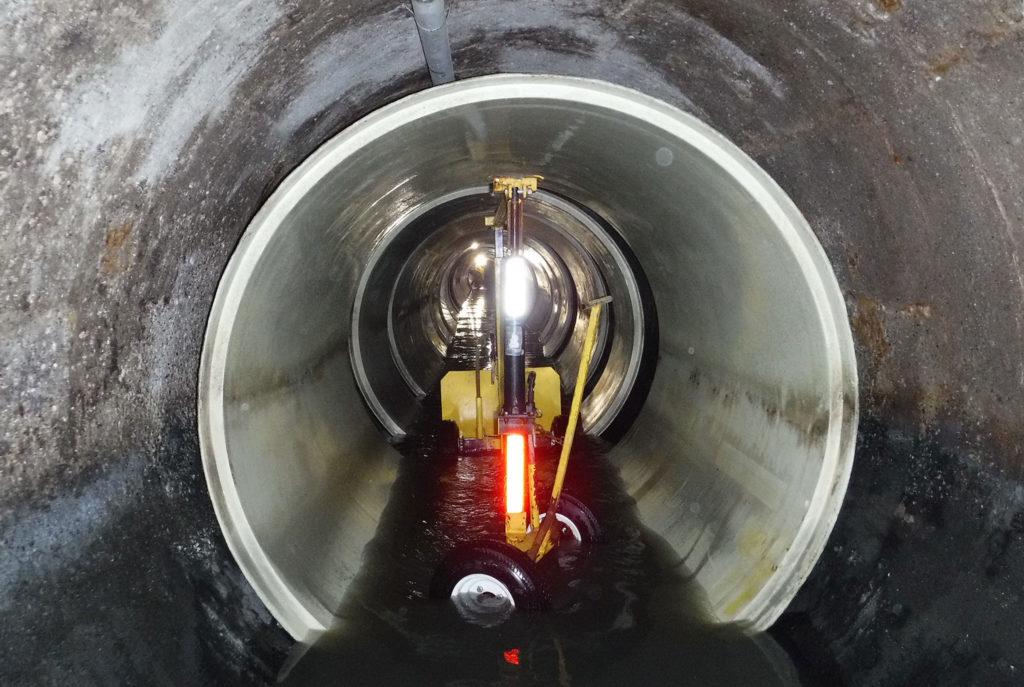

Closed Circuit Television (CCTV) sewer inspections are an essential part of evaluating your pipes’ overall condition and performance. A comprehensive digitally recorded visual inspection is a critical component to understanding your system’s condition and when creating timelines and budgets, which is why our professional team is equipped with the latest digital CCTV capable of inspecting various sized pipes.

Our team has significant experience in pipeline and maintenance hole testing operations. Their vast experience gives them the ability to know and foresee any future problems, while all asset testing is performed according to industry best practices and conforms to guidelines.

Certified to enter confined spaces while ensuring we are abiding by our strict safety policies. No work takes place in a confined space without first completing a documented atmospheric test with a calibrated gas meter and complying with the conditions of a confined space entry permit.

Laser Profiling

CCTV Inspection

Mini-Cam TV Inspection

Multi-Sensor Pipeline Inspection

UV CIPP Rehabilitation

Chemical Grouting

CIPP Spot Repairs

CIPP Mainline Rehabilitation

Culvert Rehabilitation

Dewatering & Groundwater Control

Sewer Cleaning

Hydro Blasting

GRP (Glass Reinforced Plastic) Installation

Lateral Service Line Inspection and Sealing

![]()

31 Keyes Court, Woodbridge,

Ontario L4H 4V6

Phone: 905-266-1500

Email: info@capitalinfrastructuregroup.ca